Hydrofluoric Acid Bonding System: An Overview

Introduction:

Hydrofluoric acid (HF) bonding system is a widely used adhesive in the adhesive industry. It is known for its exceptional bonding properties and is extensively used in various applications. In this article, we will delve into the performance, applications, and usage methods of the HF bonding system.

Performance:

The HF bonding system exhibits excellent adhesive properties, making it suitable for a wide range of materials. It provides high bond strength, durability, and resistance to harsh environmental conditions. The adhesive bonds formed using the HF system are known for their long-lasting performance and reliability.

Applications:

The HF bonding system finds applications in various industries, including automotive, electronics, construction, and aerospace. It is commonly used for bonding metals, ceramics, glass, and certain plastics. The adhesive is particularly effective in joining dissimilar materials, making it a preferred choice in many industries.

Usage Methods:

To achieve optimal results with the HF bonding system, it is essential to follow the correct usage methods. Here are the steps involved in using the HF bonding system:

1. Surface Preparation: Thoroughly clean and degrease the surfaces to be bonded. This ensures proper adhesion and eliminates any contaminants that may hinder the bonding process.

2. Mixing: Prepare the HF adhesive according to the manufacturer's instructions. It is crucial to follow the recommended mixing ratios and ensure thorough mixing to achieve a homogenous adhesive mixture.

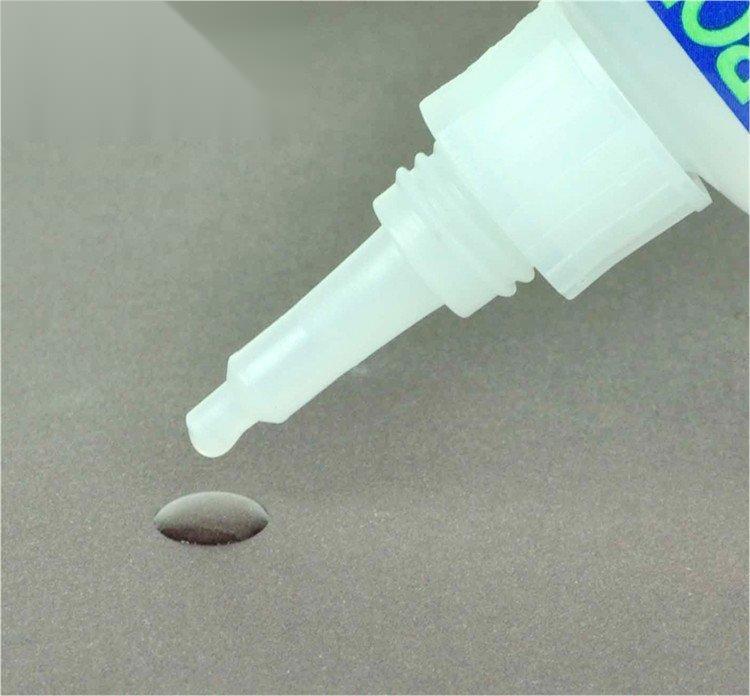

3. Application: Apply the adhesive evenly on the prepared surfaces using a brush, roller, or spray. Ensure that the adhesive is applied in a thin and uniform layer to avoid excessive buildup.

4. Bonding: Join the surfaces together immediately after applying the adhesive. Apply sufficient pressure to ensure proper contact and eliminate any air bubbles. Allow the adhesive to cure as per the manufacturer's instructions.

5. Curing: The HF bonding system typically requires a curing period to achieve maximum bond strength. Follow the recommended curing time and conditions, such as temperature and humidity, for optimal results.

Conclusion:

The HF bonding system is a versatile adhesive with exceptional performance characteristics. Its high bond strength, durability, and resistance to harsh conditions make it suitable for various applications. By following the correct usage methods, one can achieve reliable and long-lasting bonds using the HF bonding system.

This article provides an overview of the HF bonding system, highlighting its performance, applications, and usage methods. By understanding these aspects, professionals in the adhesive industry can make informed decisions regarding the use of the HF bonding system.

This article is written by the adhesive engineering department of Shiyin Adhesive Company. Please indicate the source when reproducing: \"This article is originally published by the adhesive engineering department of Shiyin Adhesive Company.\