Hydrofluoric Acid Bonding System: A Comprehensive Guide

Introduction:

Hydrofluoric acid (HF) bonding system is a widely used adhesive in the adhesive industry. It is known for its exceptional performance and versatility in various applications. In this article, we will explore the properties, applications, and usage methods of the HF bonding system.

Properties of Hydrofluoric Acid Bonding System:

The HF bonding system is characterized by its excellent bonding strength, high temperature resistance, and chemical stability. It is capable of bonding a wide range of materials, including metals, glass, ceramics, and plastics. The adhesive forms a strong and durable bond, ensuring long-lasting adhesion even under harsh conditions.

Applications of Hydrofluoric Acid Bonding System:

The HF bonding system finds extensive applications in various industries. It is commonly used in the automotive industry for bonding metal parts, such as engine components and body panels. The adhesive is also utilized in the electronics industry for bonding circuit boards and semiconductor devices. Additionally, it is employed in the construction industry for bonding glass panels and other architectural elements.

Usage Methods of Hydrofluoric Acid Bonding System:

To achieve optimal bonding results with the HF bonding system, it is essential to follow the correct usage methods. Here are the steps involved in using the adhesive:

1. Surface Preparation: Thoroughly clean and degrease the surfaces to be bonded. Remove any dirt, dust, or contaminants that may hinder the bonding process.

2. Mixing: Prepare the adhesive according to the manufacturer's instructions. Ensure proper mixing of the components to achieve a homogenous mixture.

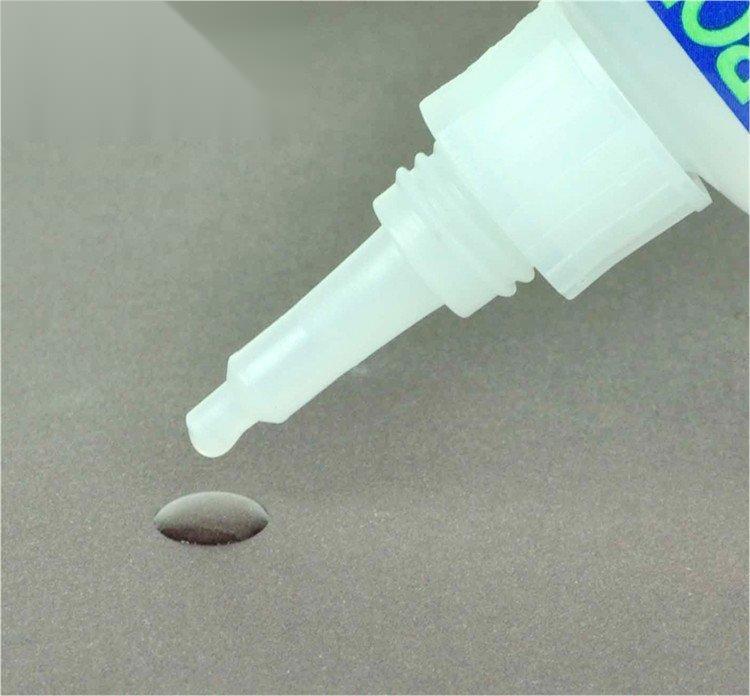

3. Application: Apply a thin and even layer of the adhesive onto one of the surfaces to be bonded. Use a brush or a suitable applicator for precise application.

4. Assembly: Carefully align the surfaces and press them together firmly. Apply sufficient pressure to ensure intimate contact between the adhesive and the substrates.

5. Curing: Allow the adhesive to cure as per the recommended curing time. This may vary depending on the specific product and application. Ensure proper curing conditions, such as temperature and humidity, for optimal bond formation.

Safety Precautions:

When working with the HF bonding system, it is crucial to prioritize safety. HF is a highly corrosive and toxic substance, and proper precautions should be taken to prevent any harm. Always wear protective gloves, goggles, and clothing when handling the adhesive. Work in a well-ventilated area or use appropriate respiratory protection. In case of contact with skin or eyes, immediately rinse with plenty of water and seek medical attention.

Conclusion:

The Hydrofluoric Acid Bonding System is a reliable and versatile adhesive that offers exceptional bonding strength and durability. Its wide range of applications and excellent performance make it a preferred choice in various industries. By following the correct usage methods and prioritizing safety, users can achieve optimal results with this adhesive.

This article has provided a comprehensive understanding of the properties, applications, and usage methods of the HF bonding system. For more information and specific product recommendations, consult with adhesive experts or manufacturers. Remember to always prioritize safety when working with any adhesive.

This article is written by the adhesive engineering department of Shiyin Adhesive. Reprinting is allowed with proper attribution.