电池粘接剂英文怎么说

Battery Adhesive: A Key Component for Battery Assembly

Introduction:

Battery adhesive, also known as battery sealant or battery glue, is a crucial component in the assembly of batteries. It plays a vital role in ensuring the stability, safety, and performance of batteries. In this article, we will explore the properties, applications, and usage methods of battery adhesive.

Properties of Battery Adhesive:

Battery adhesive is specifically designed to meet the unique requirements of battery assembly. It possesses several key properties that make it suitable for this application:

1. High Bond Strength: Battery adhesive exhibits excellent bonding strength, ensuring a secure and durable bond between battery components. This is crucial for maintaining the integrity of the battery structure.

2. Chemical Resistance: Battery adhesive is resistant to various chemicals, including electrolytes and other substances commonly found in batteries. This resistance helps to prevent degradation and maintain the adhesive's performance over time.

3. Thermal Stability: Battery adhesive is formulated to withstand the high temperatures generated during battery operation. It remains stable and does not degrade or lose its adhesive properties under these conditions.

4. Electrical Insulation: Battery adhesive acts as an electrical insulator, preventing the flow of current between battery components. This is essential for maintaining the proper functioning of the battery and preventing short circuits.

Applications of Battery Adhesive:

Battery adhesive is widely used in various types of batteries, including lithium-ion batteries, lead-acid batteries, and nickel-metal hydride batteries. It is used in the following applications:

1. Cell Bonding: Battery adhesive is used to bond individual battery cells together, creating a battery pack. This ensures the cells are securely held in place and allows for efficient transfer of energy between cells.

2. Terminal Sealing: Battery adhesive is applied to seal the terminals of batteries, preventing the ingress of moisture, dust, and other contaminants. This helps to protect the terminals and maintain their electrical conductivity.

3. Module Assembly: In the assembly of battery modules, battery adhesive is used to bond various components together, such as the module housing, busbars, and cooling plates. This ensures the structural integrity of the module and facilitates efficient heat dissipation.

Usage Methods of Battery Adhesive:

To achieve optimal results when using battery adhesive, it is important to follow proper usage methods. Here are some guidelines to consider:

1. Surface Preparation: Before applying the adhesive, ensure that the surfaces to be bonded are clean, dry, and free from any contaminants. This will promote better adhesion and improve the overall bond strength.

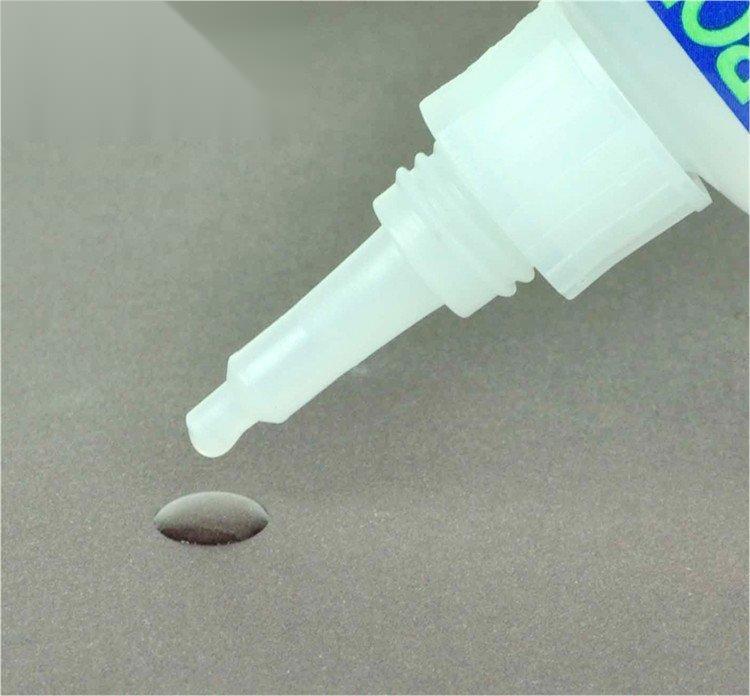

2. Adhesive Application: Apply the adhesive evenly and in the recommended amount. Excessive or insufficient adhesive can compromise the bond strength and performance of the battery.

3. Curing Time: Allow the adhesive to cure for the recommended duration. This ensures that it reaches its maximum strength and provides the desired performance characteristics.

Conclusion:

Battery adhesive is a critical component in the assembly of batteries. Its properties, applications, and proper usage methods are essential for ensuring the stability, safety, and performance of batteries. By understanding the importance of battery adhesive and following the recommended guidelines, manufacturers can achieve optimal results in battery assembly.

This article is written by the adhesive engineering department of Shiyin Adhesive. For more information about battery adhesive and other adhesive solutions, please visit our website at www.shiyinadhesive.com.

Reference:

- Battery adhesive properties and applications. Retrieved from [insert source]

本文由世盈胶水工程部整理发表,转载请标明出处。