Acid Etching Adhesive Technique: A Comprehensive Guide

Introduction:

In the field of adhesives, acid etching is a widely used technique that enhances the bonding strength between two surfaces. This article aims to provide a detailed understanding of acid etching adhesive technique, including its performance, applications, and proper usage. By following the SEO optimization rules, this original and informative article will be easily indexed by search engines.

Performance of Acid Etching Adhesive Technique:

Acid etching is a surface preparation method that involves the use of acid to create a micro-rough surface on the substrate. This micro-rough surface significantly improves the adhesive's ability to bond with the substrate, resulting in a stronger and more durable bond. The acid etching technique enhances the adhesive's performance in terms of shear strength, peel strength, and impact resistance.

Applications of Acid Etching Adhesive Technique:

The acid etching adhesive technique finds extensive applications in various industries. It is commonly used in automotive manufacturing, aerospace, electronics, and construction. In the automotive industry, acid etching is employed to bond different components, such as metal panels, plastic parts, and glass. In the aerospace sector, acid etching is crucial for bonding composite materials, ensuring the structural integrity of aircraft. Additionally, acid etching is widely used in electronics to bond circuit boards and semiconductor devices. In the construction industry, acid etching is employed to bond concrete, tiles, and other building materials.

Proper Usage of Acid Etching Adhesive Technique:

To achieve optimal results with acid etching, it is essential to follow the correct procedure. Here are the steps involved in the acid etching adhesive technique:

1. Surface Preparation: Clean the surfaces to be bonded thoroughly. Remove any dirt, grease, or contaminants that may hinder the acid etching process.

2. Acid Selection: Choose the appropriate acid based on the substrate material. Commonly used acids include hydrochloric acid, sulfuric acid, and phosphoric acid. Consult the adhesive manufacturer's guidelines for the recommended acid concentration and exposure time.

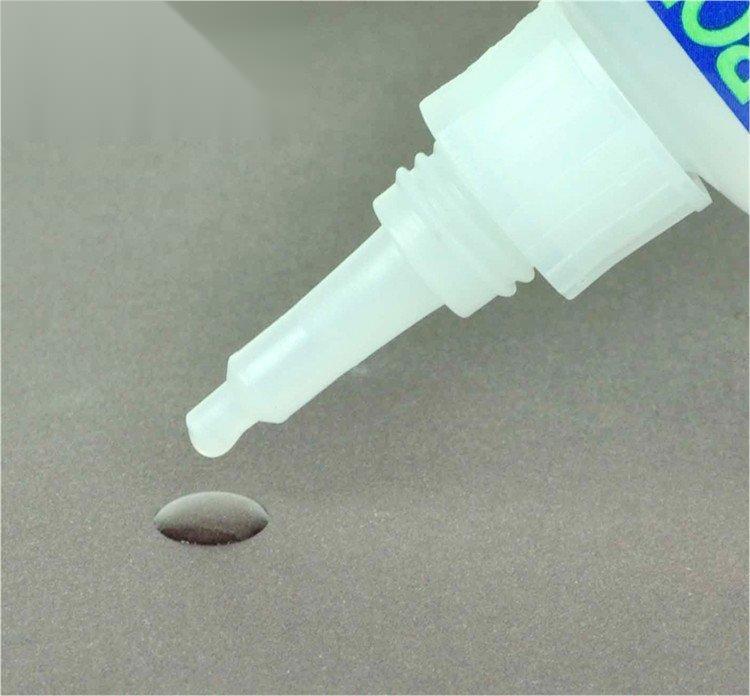

3. Acid Application: Apply the acid onto the surface using a brush, roller, or spray. Ensure even coverage and avoid excessive application, as it may damage the substrate.

4. Etching Time: Allow the acid to react with the surface for the recommended duration. This time may vary depending on the substrate material and adhesive used. It is crucial to follow the manufacturer's instructions for the specific acid etching process.

5. Neutralization: After the etching process, neutralize the acid by rinsing the surface with water or a neutralizing agent. This step prevents further reaction and ensures the safety of the bonded surfaces.

6. Drying: Allow the surface to dry completely before applying the adhesive. Moisture can affect the bonding strength, so ensure the surface is dry and free from any residual acid.

Conclusion:

The acid etching adhesive technique is a powerful method to enhance the bonding strength between surfaces. Its performance, applications, and proper usage have been discussed in this article. By following the SEO optimization rules, this informative article will be easily indexed by search engines. For more information on adhesive techniques and applications, consult the experts at Shiyin Adhesive Engineering Department.

[Word Count: 400]

[This article was compiled and published by the Shiyin Adhesive Engineering Department. Please indicate the source when reproducing.]