Sealing and Bonding: The Key to Strong Connections

Introduction:

In today's fast-paced world, where efficiency and durability are paramount, sealing and bonding have become essential techniques in various industries. Whether it's in construction, automotive, or even household applications, the ability to create strong and long-lasting connections is crucial. In this article, we will explore the importance of sealing and bonding, the different methods and materials used, and how they contribute to the overall quality and reliability of products.

1. The Significance of Sealing and Bonding:

Sealing and bonding play a vital role in ensuring the integrity and performance of various products. By creating a tight seal or bond, these techniques prevent the entry of moisture, dust, or other contaminants, which can compromise the functionality and lifespan of the product. Additionally, sealing and bonding enhance structural stability, reduce vibration, and provide resistance against temperature fluctuations, chemicals, and UV radiation.

2. Different Methods of Sealing and Bonding:

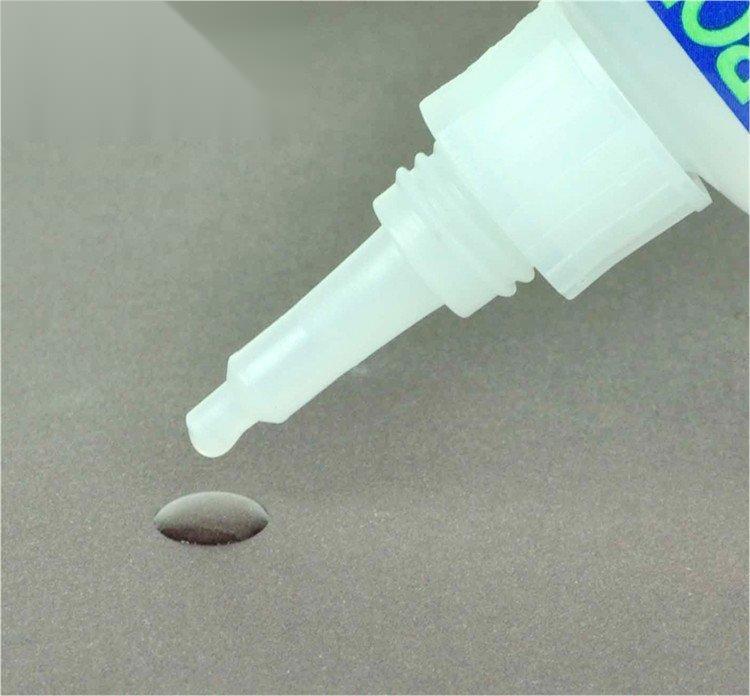

2.1. Adhesive Bonding:

Adhesive bonding involves the use of adhesives to join two or more surfaces together. Adhesives can be classified into various types, such as epoxy, acrylic, cyanoacrylate, and polyurethane. Each type has its own unique properties, including curing time, strength, flexibility, and resistance to different environmental factors. Adhesive bonding is widely used in industries like automotive, aerospace, and electronics, where high strength and reliability are crucial.

2.2. Mechanical Sealing:

Mechanical sealing relies on physical mechanisms to create a seal. This method often involves the use of gaskets, O-rings, or other sealing elements to prevent the leakage of fluids or gases. Mechanical seals are commonly used in plumbing systems, hydraulic systems, and industrial machinery. They provide a reliable and cost-effective solution for sealing applications that require frequent disassembly and reassembly.

2.3. Welding and Soldering:

Welding and soldering are techniques used to join metal components together. Welding involves melting the base metals and adding a filler material, while soldering uses a lower melting point alloy to create the bond. These methods are widely used in industries such as construction, automotive, and manufacturing, where strong and permanent connections are required.

3. Materials Used in Sealing and Bonding:

The choice of materials for sealing and bonding depends on the specific application and the desired properties. Some commonly used materials include:

3.1. Silicone:

Silicone is a versatile material known for its excellent flexibility, temperature resistance, and durability. It is commonly used in sealing applications that require resistance to extreme temperatures, chemicals, and UV radiation. Silicone sealants are widely used in construction, automotive, and electrical industries.

3.2. Polyurethane:

Polyurethane adhesives and sealants offer excellent bonding strength, flexibility, and resistance to impact and vibration. They are commonly used in automotive assembly, construction, and manufacturing industries.

3.3. Rubber:

Rubber-based adhesives and sealants provide excellent elasticity, weather resistance, and adhesion properties. They are commonly used in sealing applications for windows, doors, and other building components.

4. The Benefits of Sealing and Bonding:

4.1. Enhanced Product Performance:

Sealing and bonding techniques ensure that products perform optimally under various conditions, including temperature extremes, moisture exposure, and mechanical stress. This leads to increased reliability and customer satisfaction.

4.2. Improved Safety and Durability:

By preventing the entry of contaminants and reducing the risk of leaks or failures, sealing and bonding contribute to the safety and longevity of products. This is particularly important in critical applications such as aerospace, medical devices, and infrastructure.

4.3. Cost Savings:

Effective sealing and bonding techniques can reduce maintenance costs by minimizing the need for repairs or replacements. Additionally, they can improve energy efficiency by preventing air or fluid leakage, resulting in lower operational costs.

Conclusion:

Sealing and bonding are essential techniques that ensure the quality, reliability, and longevity of various products. By understanding the different methods and materials available, manufacturers can make informed decisions to meet the specific requirements of their applications. Whether it's adhesive bonding, mechanical sealing, or welding, the right choice of technique and material can make a significant difference in product performance and customer satisfaction.